how to use a refractometer to test coolant|cnc coolant refractometer chart : maker This video explains how to: • recognise key parts of the refractometer • configure / set up a refractometer • test engine coolant with a refractometer (check antifreeze). Get the know-how. We use this high accuracy controller for our high temperature muffle furnaces, tube furnaces, and vacuum furnaces. • Fully Automated, SET and FORGET operation. We provide essential .

{plog:ftitle_list}

Autoclave Repair - Free Technical Support - Whether its a Midmark M11, Tuttnauer, Pelton Crane, Statim. Tuttnauer or other Autoclave brands, Allclaveparts.com has everything you need to repair your own autoclaves.Steam-flush pressure pulse air removal system ensures proper steam sterilization. Easy to Use. Pre-programmed sterilization cycles and intuitive LCD display with prompts ensure quick, confident operation. Safe. Real-time alerts notify users promptly of any critical system errors. Award Winning.

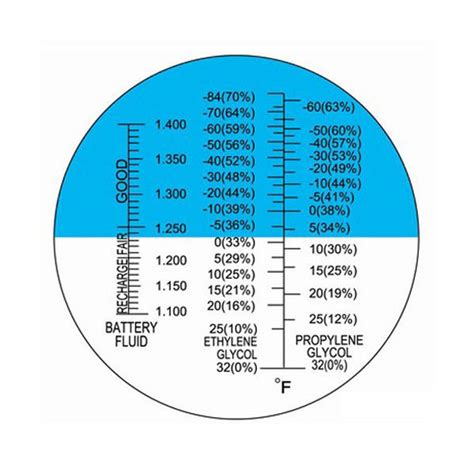

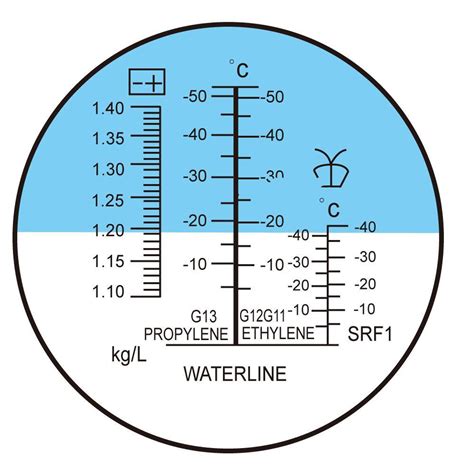

A refractometer is used to measure the freezing point of vehicle coolant, washer fluid, and potentially also testing battery electrolyte. This short video demonstrates how to use a.

This video explains how to: • recognise key parts of the refractometer • configure / set up a refractometer • test engine coolant with a refractometer (check antifreeze). Get the know-how. A refractometer is used to measure the freezing point of vehicle coolant, washer fluid, and potentially also testing battery electrolyte. This short video demonstrates how to use a. This video explains how to: • recognise key parts of the refractometer • configure / set up a refractometer • test engine coolant with a refractometer (check antifreeze). Get the know-how. TEST your coolant. Using a dropper, extract coolant from your machine. Again using the dropper, place 2–3 drops of coolant onto the prism of the refractometer and carefully secure its cover plate. Make sure there are no dry spots or .

Use a refractometer to check antifreeze coolant concentration. The correct strength antifreeze coolant is important, hydrometers are often not very accurate tool to check the ratios..To test coolant with a refractometer, follow these steps: Extract coolant or fluid from your machine using a dropper. Place 2–3 drops of coolant onto the prism of the refractometer and secure its cover plate.

How to test coolant using all three methods. Test for freeze protection. Test for pH and alkalinity and test for electrolysisUsing a Refractometer: Check the calibration of your refractometer. Water at 68° F should read 0.0 percent Brix. Open the cover plate and place a drop of plain water (no coolant) on the prism surface (see Figure 1). Close the cover plate to spread water over surface.

Your coolant’s current freeze point is found by using a coolant tester, also known as a bubble gauge, or refractometer. Since bubble gauge-style antifreeze testers are very common and affordable, we'll be describing their use in the remainder of this article.

Refractometers provide a quick, easy, and accurate way of testing and controlling coolant concentration. Watch Kurt Repsher demonstrate the correct way to us. Coolants must operate within a specific concentration window to maintain the right amount of lubricity and additive content. Refractometers are instruments used to obtain a °Brix reading, which measures the oil content present in a coolant mixture. A refractometer is used to measure the freezing point of vehicle coolant, washer fluid, and potentially also testing battery electrolyte. This short video demonstrates how to use a.

This video explains how to: • recognise key parts of the refractometer • configure / set up a refractometer • test engine coolant with a refractometer (check antifreeze). Get the know-how. TEST your coolant. Using a dropper, extract coolant from your machine. Again using the dropper, place 2–3 drops of coolant onto the prism of the refractometer and carefully secure its cover plate. Make sure there are no dry spots or . Use a refractometer to check antifreeze coolant concentration. The correct strength antifreeze coolant is important, hydrometers are often not very accurate tool to check the ratios..To test coolant with a refractometer, follow these steps: Extract coolant or fluid from your machine using a dropper. Place 2–3 drops of coolant onto the prism of the refractometer and secure its cover plate.

How to test coolant using all three methods. Test for freeze protection. Test for pH and alkalinity and test for electrolysisUsing a Refractometer: Check the calibration of your refractometer. Water at 68° F should read 0.0 percent Brix. Open the cover plate and place a drop of plain water (no coolant) on the prism surface (see Figure 1). Close the cover plate to spread water over surface.Your coolant’s current freeze point is found by using a coolant tester, also known as a bubble gauge, or refractometer. Since bubble gauge-style antifreeze testers are very common and affordable, we'll be describing their use in the remainder of this article. Refractometers provide a quick, easy, and accurate way of testing and controlling coolant concentration. Watch Kurt Repsher demonstrate the correct way to us.

refractometer reading chart

lamotte total hardness test kit

*Chemical indicator = autoclave tape or chemical integrator pack.

how to use a refractometer to test coolant|cnc coolant refractometer chart